The technology behind catalytic converters has advanced over the years, making them more efficient and effective in reducing emissions and protecting the environment.

Catalytic converters are designed to convert harmful exhaust gases into less toxic substances before they are released into the environment. We already know that palladium, platinum, and rhodium are the crucial catalysts present in the converter. But considering the high prices of rhodium, people frequently ask, how much rhodium in a catalytic converter?

On average, 1-2 grams of rhodium is present in one catalytic converter. But the quantity may vary by model and other factors.

The Role of Rhodium in a Catalytic Converter

Rhodium plays a crucial role in reducing harmful emissions from internal combustion engines by acting as a catalyst in catalytic converters. The harmful gases produced by an internal combustion engine, such as nitrogen oxides (NOx), hydrocarbons (HC), and carbon monoxide (CO), are passed through the catalytic converter, where they come into contact with the rhodium catalyst.

The rhodium catalyst provides a surface for chemical reactions to occur on, and its unique properties, including its high thermal stability and resistance to corrosion, make it an ideal material for catalytic converters.

Comparison to other Catalytic Metals

Rhodium is one of several metals that are used as catalysts in catalytic converters such as platinum, palladium, and iridium. However, rhodium has some distinct advantages over these other metals, making it a valuable material for catalytic converters.

One advantage of rhodium is its high thermal stability, which makes it resistant to degradation at high temperatures, an important consideration in the high-heat environment of a vehicle’s exhaust system.

- Rhodium also has a high melting point, which makes it less prone to melting and losing its catalytic properties under extreme conditions.

- Another advantage of rhodium is its ability to efficiently catalyze the reduction of nitrogen oxides (NOx), a major contributor to air pollution. Rhodium is able to catalyze the conversion of NOx into nitrogen and oxygen, making it an effective material for reducing emissions of this harmful gas.

- In comparison, platinum and palladium are also widely used catalytic metals, but they are less effective at catalysing the reduction of NOx. Iridium, while a highly effective catalyst for NOx reduction, is more expensive and less abundant than rhodium, making it a less cost-effective choice for catalytic converters.

In nutshell, while there are several catalytic metals available, rhodium has several unique properties that make it an ideal choice for catalytic converters.

Factors that influence the amount of rhodium used in a catalytic converter

The amount of rhodium used in a catalytic converter can be influenced by several factors, including:

Emissions standards

The more stringent the emissions standards set by regulatory agencies, the more rhodium may be required to meet those standards. In areas with particularly high air pollution levels, more rhodium may be used in catalytic converters to effectively reduce harmful emissions.

Engine size and type

The size and type of the engine will impact the amount of rhodium needed in a catalytic converter. For example, larger engines may require more rhodium to effectively reduce emissions, while diesel engines, which produce different types of emissions compared to gasoline engines, may require a different amount of rhodium.

Cost

The cost of rhodium is another factor that can influence the amount used in catalytic converters. As the price of rhodium is high, manufacturers may use it less in order to keep the cost of the catalytic converter down for affordable segment vehicles.

By considering these factors, manufacturers can optimize the use of rhodium to effectively reduce harmful emissions while also balancing cost and efficiency.

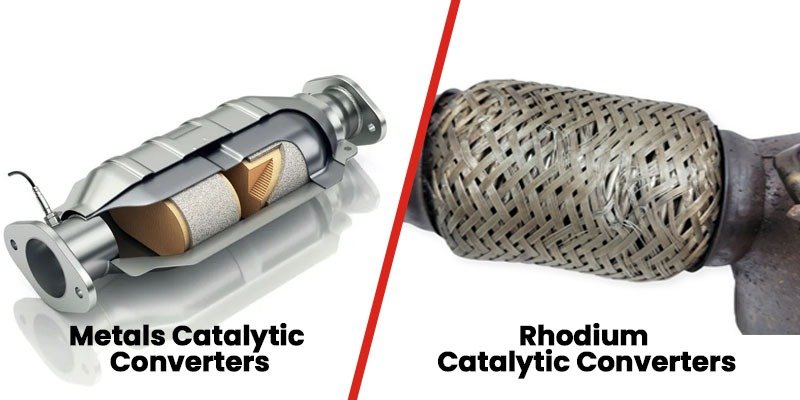

Other Metals Vs Rhodium in Catalytic Converters

Rhodium is one of the metals used in catalytic converters, and it is highly valued for its catalytic properties. Other metals used in catalytic converters include palladium, platinum, and ceramic. Palladium, for example, is less expensive than rhodium and has similar catalytic properties, making it a popular alternative.

Cost considerations for manufacturers

The cost of rhodium has a significant impact on the cost of manufacturing catalytic converters. Rhodium is a rare and expensive metal, which drives up the cost of catalytic converters that contain it. Manufacturers are constantly searching for cost-effective alternatives, such as palladium or ceramic, to reduce production costs.

Why the amount of rhodium can vary?

Oxidation converters are used in diesel vehicles and work by oxidizing carbon monoxide and hydrocarbons into carbon dioxide and water vapor. Three-way converters, which are commonly used in gasoline vehicles, perform both oxidation and reduction reactions. They reduce nitrogen oxides into nitrogen and oxygen and oxidize carbon monoxide and hydrocarbons into carbon dioxide and water vapor. Diesel oxidation converters are similar to oxidation converters, but are specifically designed for diesel engines.

Rhodium is one of the metals used in catalytic converters, and it is highly valued for its catalytic properties. Other metals used in catalytic converters include palladium, platinum, and ceramic. Palladium, for example, is less expensive than rhodium and has similar catalytic properties, making it a popular alternative.

The cost of rhodium has a significant impact on the cost of manufacturing catalytic converters. Rhodium is a rare and expensive metal, which drives up the cost of catalytic converters that contain it. Manufacturers are constantly searching for cost-effective alternatives, such as palladium or ceramic, to reduce production costs.

Importance of Rhodium as a Catalytic Metal: What is Rhodium Used for?

Rhodium is a precious metal that has a high value due to its unique properties, including its use as a catalytic metal. A catalytic metal is a substance that speeds up a chemical reaction without being consumed in the process. This makes rhodium a crucial component in many industrial and technological applications.

Here are some of the reasons why rhodium is important as a catalytic metal:

Automotive Catalysts:

Rhodium is a critical component in catalytic converters, which are used in cars to reduce harmful emissions from exhaust. Rhodium acts as a catalyst to convert toxic pollutants into less harmful substances.

Petroleum Refining:

Rhodium is used in catalysts to produce high-octane gasoline and diesel fuel. This helps to improve the efficiency and sustainability of the refining process.

Chemical Synthesis

Rhodium is used as a catalyst in the synthesis of various chemicals, such as perfumes, pharmaceuticals, and plastics. This allows for faster and more efficient production of these materials.

Environmental Protection

Rhodium catalysts are used in various industrial processes to remove impurities and pollutants from gases and liquids. This helps to protect the environment and prevent contamination.

Hence rhodium plays a vital role as a catalytic metal, contributing to the efficiency and sustainability of various industrial processes and technologies. Its unique properties and scarcity make it a valuable and essential material for modern society.

Comparison of Catalytic Converters Used in Different Countries

Catalytic converters are significant for the automotive industry. However, there can be differences in the type of catalytic converters used in different countries based on various factors such as local regulations, fuel quality, driving conditions, and vehicle technology.

In the United States, the use of catalytic converters has been mandatory since the 1975, and the regulations have become more stringent over time to reduce emissions of nitrogen oxides (NOx), hydrocarbons (HC), and carbon monoxide (CO). A three-way catalytic converters, which are effective in reducing all three types of emissions.

In Europe, catalytic converters have been required on vehicles since the 1990s, and the regulations are similarly stringent as in the US. However, European countries also have to comply with the European Union’s emission standards, which are known as Euro standards. Currently, the most common type of catalytic converter used in Europe is the diesel particulate filter (DPF) that reduces particulate matter emissions from diesel engines.

In Japan, catalytic converters have been required on vehicles since the 1980s, and the regulations are similar to those in the US and Europe. However, the Japanese automotive industry has a strong focus on fuel efficiency, and as a result, Japanese vehicles often use lighter and smaller catalytic converters to improve fuel economy.

In China, the use of catalytic converters has become mandatory in 2000. However, the Chinese government is taking steps to improve air quality and reduce emissions, and the regulations are expected to become more stringent in the future.

It’s worth noting that different countries might also use different materials and technologies in their catalytic converters, depending on the type of fuel used, driving conditions, and the vehicles they are fitted on.

Frequently Asked Questions

Which Catalytic Converters Have the Most Rhodium?

Toyota Prius has the most rhodium in its catalytic converter. Hence, the new converter in the market costs more than $2000 owing to the presence of an expensive catalyst such as rhodium, platinum, and other materials.

How Much is 1 g of Rhodium Worth?

The current price of rhodium as of February 2023 is $393 per gram. Hence, people often doubt if rhodium is present in catalytic converters owing to its exorbitant pricing. The answer is yes! For all the expensive models, rhodium is present in their catalytic converter justifying their higher pricing.

Where do you find scrap rhodium?

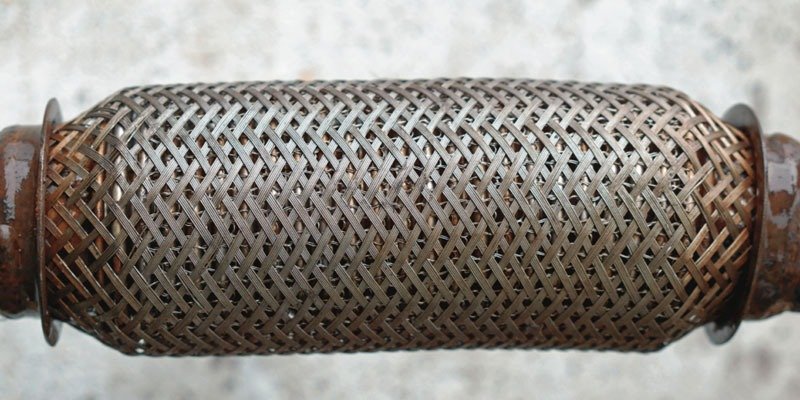

Scrap rhodium can be found at metal recycling centers, as well as through online scrap dealers and metals exchanges. Most of the recycled rhodium comes from platinum group metals by autocatalysts recycling. These PGM are available within the honeycomb structure of the catalytic converter. in the It is one of the reasons why old catalytic converter has a high value in the scrap market and converter theft is at peak.

Conclusion

In conclusion, catalytic converters play a vital role in reducing harmful emissions from vehicles, making them an essential component of modern vehicle exhaust systems. The three main types of converters, oxidation, three-way, and diesel oxidation, vary in their composition and the average weight of rhodium used, with three-way converters containing the most rhodium.

The cost of rhodium, which is a rare and expensive metal, is a significant consideration for manufacturers, and alternatives such as palladium are being sought to reduce production costs. The widespread use of catalytic converters has resulted in improved air quality and a reduction in the negative impacts of vehicle emissions on human health and the environment.

My Name is Christopher Angels, and I am a postgraduate in mechanical engineering. Cars have always excited me as a child, and soon I decided to dive into the world of cars by pursuing mechanical engineering. I also worked as a Mechanic for over 3 years to understand Cars’ anatomy and how each part contributes to its working.

My Name is Christopher Angels, and I am a postgraduate in mechanical engineering. Cars have always excited me as a child, and soon I decided to dive into the world of cars by pursuing mechanical engineering. I also worked as a Mechanic for over 3 years to understand Cars' anatomy and how each part contributes to its working.