Emissions reduction is an important aspect of diesel engine technology. Diesel engines emit a variety of harmful pollutants that can have significant environmental and health impacts. Regulations and standards have been put in place to reduce emissions from diesel engines. The use of emission control systems, such as catalytic converters and diesel particulate filters, is an effective way to reduce emissions. They ensure that diesel vehicles remain a cleaner and more environmentally friendly option for transportation.

Catalytic converters are widely used in both gasoline and diesel engines to reduce emissions of harmful pollutants. In diesel engines, catalytic converters are used in conjunction with other emission control systems to reduce nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC) emissions.

In this blog post, we will discuss the requirements of catalytic converters, their role in diesel engines, and their working.

How Catalytic Converters Work in Diesel Engines?

A catalytic converter is a device installed in the exhaust system of a vehicle that helps reduce emissions of harmful pollutants. In a diesel engine, a catalytic converter works by converting harmful pollutants, such as nitrogen oxides (NOx), carbon monoxide (CO), and hydrocarbons (HC), into less harmful substances through a chemical reaction.

The catalytic converter contains a ceramic or metal substrate coated with catalysts, such as platinum, palladium, and rhodium. The substrate acts as a support structure for the catalysts, while the catalysts activate the chemical reactions that convert the pollutants. When exhaust gases from the diesel engine pass through the catalytic converter, the catalysts initiate reactions that convert NOx into nitrogen and water vapor, CO into CO2, and HC into CO2 and water vapor.

The catalytic converter operates at high temperatures, usually around 500-900°C, which is achieved by the heat generated from the exothermic reactions taking place inside the converter. High temperatures are essential for catalytic reactions to occur efficiently. The heat also helps to oxidize any unburned hydrocarbons in the exhaust gas stream, further reducing emissions.

What Are the Benefits of Using Catalytic Converters in Diesel Engines?

The use of catalytic converters in diesel engines provides numerous benefits.

- It helps reduce emissions of harmful gaseous emissions such as carbon monoxide, soluble organic fractions such as polynuclear aromatics, and unburn hydrocarbons that are detrimental to both human health and the environment.

- Additionally, it helps diesel engines meet emissions regulations and standards, thus reducing the risk of penalties and fines.

- Using catalytic converters also helps to improve fuel efficiency, as less energy is lost in the conversion of pollutants.

- As these converters operate at 90 percent efficiency that virtually eliminates the diesel odor along with controlling visible particulates.

What are the Types of Catalytic Converters Used in Diesel Engines:

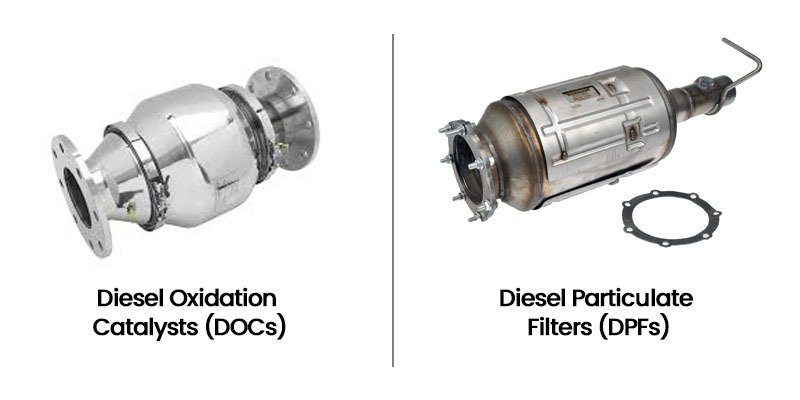

There are two main types of catalytic converters used in diesel engines:

- Diesel Oxidation Catalysts (DOCs)

- Diesel Particulate Filters (DPFs).

DOCs are used to reduce CO and HC emissions, while DPFs are used to reduce particulate matter (PM) emissions. Some diesel engines also use selective catalytic reduction (SCR) systems, which work in conjunction with DOCs and DPFs to further reduce NOx emissions. These systems use a urea-based reducing agent to convert NOx into nitrogen and water vapor.

The widespread use of catalytic converters in diesel engines will help ensure that diesel vehicles remain a cleaner and more environmentally friendly option for transportation.

“Diesel engines are widely used in transportation and industrial applications, but they also emit harmful pollutants that can have significant environmental and health impacts. Emissions reduction is therefore an important aspect of diesel engine technology.”

What are the Environmental and Health Impacts of These Diesel Pollutants?

Diesel engines emit a variety of harmful pollutants, including nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), and hydrocarbons (HCPM is a mixture of solid and liquid particles that can penetrate deep into the lungs, causing respiratory problems.

The harmful pollutants emitted by diesel engines can have significant environmental and health impacts.

- NOx emissions can lead to the formation of ground-level ozone, which can harm crops, forests, and other vegetation. It can also cause respiratory problems and exacerbate existing health conditions, such as asthma. NOx is a major contributor to air pollution and can lead to the formation of smog and acid rain. NOx is a major contributor to air pollution and can lead to the formation of smog and acid rain.

- PM emissions can contribute to the formation of particulate matter, which can penetrate deep into the lungs and cause respiratory problems.

- CO emissions can cause headaches, dizziness, and nausea in high concentrations and can also harm the environment by contributing to ground-level ozone formation. ). CO is a toxic gas that can cause headaches, dizziness, and nausea in high concentrations.

- HC emissions can contribute to the formation of ground-level ozone and smog. HCs are volatile organic compounds that can contribute to ground-level ozone and smog formation.

What are the regulations and standards in place to reduce emissions from diesel engines?

To address the harmful impacts of diesel engine emissions, various regulations and standards have been put in place to reduce emissions from diesel engines.

- The Environmental Protection Agency (EPA) in the United States sets emissions standards for diesel engines under the Clean Air Act.

- The European Union has similar regulations, known as the Euro emissions standards, that set limits on emissions from diesel engines. As on September 2022, Euro 6 is applicable for diesel engines. Infact, Euro 7 will be applicable effective from July 1, 2025 for the new cars to lower the emissions by 35% and the tailpipe particulate to be reduced by 17% as compared to the existing Euro 6 standard.

These regulations require diesel engine manufacturers to install emission control systems, such as catalytic converters and diesel particulate filters, on their engines to reduce emissions of harmful pollutants.

Historical background of catalytic converters in diesel engines

The use of catalytic converters in diesel engines can be traced back to the 1970s, when the first catalytic converters were introduced for gasoline engines. The introduction of catalytic converters for diesel engines came much later, in the 1990s, as diesel engines became more widely used in transportation and industrial applications. At first, diesel engine manufacturers faced challenges in developing effective catalytic converters for diesel engines due to the high levels of nitrogen oxides (NOx) and particulate matter (PM) emitted by diesel engines.

Advancements and Innovations in catalytic converters for Diesel Engines

Over the years, advancements and innovations in catalytic converter technology have made it possible to effectively reduce emissions from diesel engines.

For example, the development of diesel particulate filters (DPFs) has greatly reduced PM emissions from diesel engines, while advancements in catalytic converter materials and catalysts have improved their efficiency in reducing NOx emissions.

In recent years, the use of selective catalytic reduction (SCR) systems has become increasingly popular for reducing NOx emissions from diesel engines. These systems use a chemical reducing agent, such as urea, to convert NOx into nitrogen and water vapor.

Current state of catalytic converters in diesel engines:

Today, catalytic converters are widely used in diesel engines to reduce emissions of harmful pollutants, such as NOx, CO, and HC. They have become an essential component of diesel engine emission control systems, and their use is mandatory in many countries in order to meet emissions regulations.

The current state of catalytic converters in diesel engines is characterized by continued advancements and innovations in technology, as well as an increasing focus on reducing emissions from diesel engines and promoting sustainable transportation.

Conclusion

The evolution of catalytic converters in diesel engines has been a story of continued advancements and innovations in technology. Today, catalytic converters are widely used in diesel engines to effectively reduce emissions of harmful pollutants and promote sustainable transportation. The continued focus on emissions reduction and advancements in catalytic converter technology will likely lead to further improvements in the efficiency and effectiveness of catalytic converters in diesel engines in the future.

My Name is Christopher Angels, and I am a postgraduate in mechanical engineering. Cars have always excited me as a child, and soon I decided to dive into the world of cars by pursuing mechanical engineering. I also worked as a Mechanic for over 3 years to understand Cars’ anatomy and how each part contributes to its working.

My Name is Christopher Angels, and I am a postgraduate in mechanical engineering. Cars have always excited me as a child, and soon I decided to dive into the world of cars by pursuing mechanical engineering. I also worked as a Mechanic for over 3 years to understand Cars' anatomy and how each part contributes to its working.